Truck-Lite

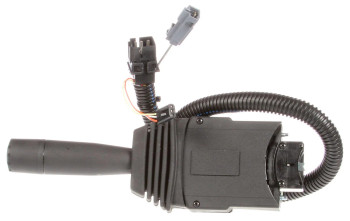

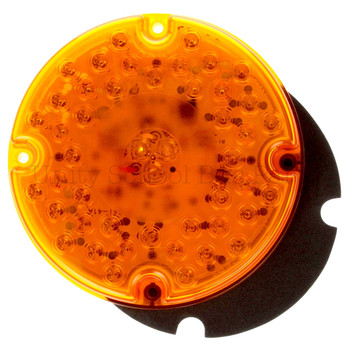

4805AAY115, Truck-Lite Yellow Freightliner Front Turn Signal

- SKU:

- 4805AAY115

- Shipping:

- Calculated at Checkout

Description

- 4805AAY115

- Yellow Freightliner Front Turn Signal

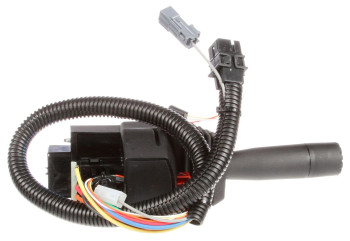

- Includes OEM 7" harness that mates with truck harness - simplifying replacement

- Dual optic lens

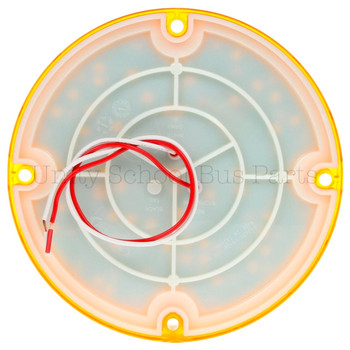

- Housing and Lens Material: Polycarbonate (Plastic)

- Side marker and reflector included in design

- Mounting pad included

- Two 5/16" studs on 2" centers

- Common Size: 4"x4"

- Current Minor: 0.5

- Housing Color: Black

- Kit: No

- Lens Shape: Square

- Incandescent Lighting

- Lamp Connection: Hardwired

- Mounting Orientation: Vertical

- Mount Type: 2 Stud Mounts

- Number of Diodes/Bulbs: 2

- Number of Wires: 3

- Plug Side One: Hardwired

- Plug Side Two: Packard Connector 12010996, Packard Connector 12010973

- Position: Universal

- Sealed/Bulb Replaceable: Bulb Replaceable

- Side Marker: Yes

- Standards Met: I6|A

- Voltage: 12

- Made in the USA

- 1 Year Warranty

Works with the below Part#'s:

- Turn Signal Bulb (10/Pack): 1156

- Side Marker Bulb (10/Pack): 1895

- Replacement Lens Part#: 9079A

- Lens Only Part#: 9080A

Cross#'s: 1983088, SS4805AAY115-S, 25172900, 12010996, 12010973, 681-822-0020

VMRS: 034-003-010

What lights do I need?

Check the specific vehicle requirements or contact Truck-Lite Technical Support. Note that states cannot require anything different than what is in FMVSS-108; however, states can add regulations. Contact Truck-Lite for special situations.

How hard should I tighten down (torque) plastic lights or devices?

Over-torqueing will generally cause cracking or distortion. Use the torque specifications provided by the manufacturer. A marker light will generally be in the neighborhood of 8 to 20 inch lbs., but a good rule of thumb is to use the minimum torque necessary to secure the device.

I'm painting my vehicle, what if I get some paint on the lens?

You should be careful to avoid getting paint on the lights; most paints (excluding water based) are incompatible with polycarbonate lights. They may also cause wires or cable insulation to crack.

What's the difference between an acrylic and polycarbonate lens?

Given its weather resistance and clarity, acrylic has long been the most widely used material for lenses. However, polycarbonate is much less likely to shatter, chip or crack upon impact and can withstand higher exposure to heat. Polycarbonate lenses are given a special coating to improve abrasion, UV and chemical resistance; still, to prolong the life of your lenses, it is recommended that you only clean them with a mild detergent and soft cotton cloth.

The following solvents/cleaners MUST NOT be used with polycarbonate:

- Trichlor

- Acetone

- Triclene®

- Methyl Ethyl Keytone (MEK)

- MIBK

- Toluol

- Benzol

- Gasoline

- Carbon Tetrachloride

- Chlorinated Hydrocarbons

- Texize-8006, 8129, 8758

- Liquid Cleaner - 8211

- Agitene®

- Ajax®

- All Liquid Detergents

- Pink Lux® (phosphate free)

- Diversol®

- Lemon Joy® (phosphate free)

- Kleenol Plastics

- Lestoil®

- Lysol®

- Stanisol Naphtha®

- Oils