Truck-Lite

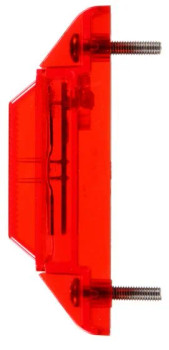

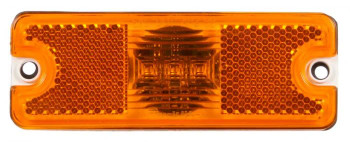

26353R, Truck-Lite Model 26 Clearance/Marker Light (Red)

- SKU:

- 26353R

- Shipping:

- Calculated at Checkout

Description

- 26353R

- Truck Lite Model 26 Clearance/Marker Light

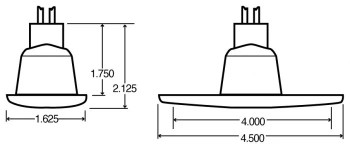

- 1 1/2"x 3 3/4"

- Surface Mounts on Two Screws at 1.5" Centers

- Ground Through Base

- Popular for Use on School and Commercial Buses

- Heavy duty steel and acrylic construction

- Lens attaches to base with one center screw

- Replaces Signal-Stat 1151/1151A/9251

- Voltage: 12

- Warranty: 3 years

- Lighting Technology: Incandescent

- Number of Diodes/Bulbs: 1

- Number of Wires: 1

- Series: 26

- Lamp Connection: Hardwired

- Plug Side One: Hardwired

- Plug Side Two: Stripped End

- Lens Shape: Rectangular

- Lens Color: Red

- Housing Material: Steel

- Lens Material: Acrylic

- Compliance Family: FMVSS 108 / CMVSS 108 / DOT / SAE

- Mount Type: Bracket Mount Kits

- Wire Gauge: 18

Replacement Lens Part#: 99170R

Cross#'s: 2092113, 26353R4, 25172900

VMRS: 034-004-021

What are combination marker/clearance lights, and how do I mount them?

A combination marker/clearance light is one light doing the work of two. It must be at a 45-degree angle (on corners) to be legal. It needs to be marked “PC” in the lens code. For further information, contact Truck-Lite.

What lights do I need?

Check the specific vehicle requirements or contact Truck-Lite Technical Support. Note that states cannot require anything different than what is in FMVSS-108; however, states can add regulations. Contact Truck-Lite for special situations.

How hard should I tighten down (torque) plastic lights or devices?

Over-torqueing will generally cause cracking or distortion. Use the torque specifications provided by the manufacturer. A marker light will generally be in the neighborhood of 8 to 20 inch lbs., but a good rule of thumb is to use the minimum torque necessary to secure the device.

I'm painting my vehicle, what if I get some paint on the lens?

You should be careful to avoid getting paint on the lights; most paints (excluding water based) are incompatible with polycarbonate lights. They may also cause wires or cable insulation to crack.

What's the difference between an acrylic and polycarbonate lens?

Given its weather resistance and clarity, acrylic has long been the most widely used material for lenses. However, polycarbonate is much less likely to shatter, chip or crack upon impact and can withstand higher exposure to heat. Polycarbonate lenses are given a special coating to improve abrasion, UV and chemical resistance; still, to prolong the life of your lenses, it is recommended that you only clean them with a mild detergent and soft cotton cloth.